Contact Us

- Hot Line

- 400-048-8890

- ADD:77# huashi road,beichen science & technology park,

- TEL:022-26998183

- FAX:022-26996185

- EMAIL:tpyphe@sina.com

- ZIP:300409

Equipment Repair:

1. Equipment in the regular maintenance and dismantling methods

A. Plate heat exchanger in addition to special circumstances of the maintenance, but also the regular maintenance, for the equipment structure is serious, the resistance increases the normal use, the use of the heat exchanger to remove the cleaning method is generally recommended to remove the cleaning The cycle is as follows:

Minor fouling fluid: 3 years

General scaling fluid: 1 year

Severe fouling of the crystalline fluid: half a year or less

B. When using the heat exchanger to clean the surface of the heat exchanger, you can use high pressure water or steam spray; can spray warm water (sometimes add some cleaning agent) and then bristle brush metal plate (Note: Brush and use the saw blade, so as not to scratch the surface protective film damage or so that the plate can not be pressed, affecting the seal.

C. For the removal of surface fouling, chemical cleaning can be used.

Cleaning and maintenance steps:

1. Preliminary inspection: the use of high temperature, corrosive media used in stainless steel sheet and gasket to make a preliminary analysis of the aging analysis. Machine to our site after the water pressure test to detect whether there is leakage. Such as the discovery of leakage first determine the location of the leakage plate in order to open after the focus to check. After the hydrostatic test record the number of heat exchanger plate, clamping size and other data.

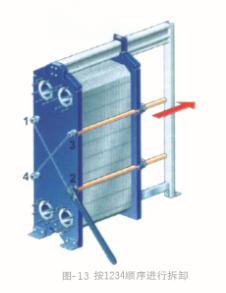

2. Remove the heat exchanger: emptying the liquid in the heat exchanger, loosening the clamping nut of the heat exchanger, removing it in the order of 1234 in the figure, and pushing the movable pressing plate to the end, Take off.

3. Check the plate and gasket on a piece-by-piece basis, and focus on the location of the leakage test. On the number of panels and gaskets that can not be continued to be used, communicate with the user for replacement.

4. Plate cleaning:

(1) First, spray the cleaning with a water gun that is easy to remove

(2) the initial cleaning of the plate into the cleaning tank, with a special chemical agent soaking, after the bubble and then washed with water until the dirt removed.

5. After the plate is cleaned, check whether the plate has perforation due to the removal of dirt.

6. Reassemble the plates in the original form, clamping the clamps in place according to the data recorded at the time of disassembly.

7. After assembly, according to the nameplate design pressure of 1.3 times the water pressure test, each side of the pressure 30 minutes without leakage is qualified.